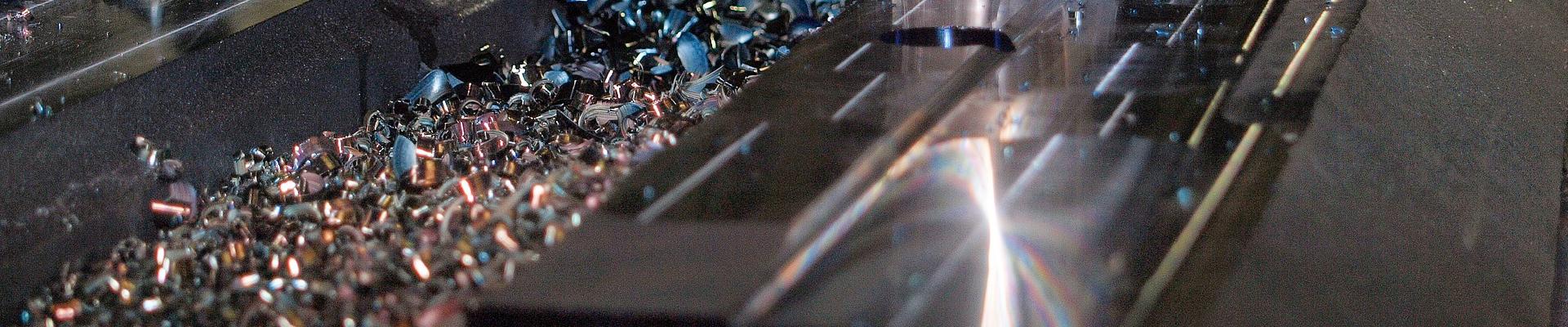

Machining is any process in which a cutting tool is used to remove small chips of material from the workpiece (the workpiece is often called the “work”). To perform the operation, relative motion is required between the tool and the work. This relative motion is achieved in most machining operation by means of a primary motion, called “cutting speed” and a secondary motion called “feed”.[7] The shape of the tool and its penetration into the work surface, combined with these motions, produce the desired shape of the resulting work surface.

Machining operations

There are many kinds of machining operations, each of which is capable of generating a certain part geometry and surface texture.

In turning, a cutting tool with a single cutting edge is used to remove material from a rotating workpiece to generate a cylindrical shape. The primary motion is provided by rotating the workpiece, and the feed motion is achieved by moving the cutting tool slowly in a direction parallel to the axis of rotation of the workpiece.

Drilling is used to create a round hole. It is accomplished by a rotating tool that typically has two or four helical cutting edges. The tool is fed in a direction parallel to its axis of rotation into the workpiece to form the round hole.

In boring, a tool with a single bent pointed tip is advanced into a roughly made hole in a spinning workpiece to slightly enlarge the hole and improve its accuracy. It is a fine finishing operation used in the final stages of product manufacture.

Reaming is one of the sizing operations that removes a small amount of metal from a hole already drilled.

In milling, a rotating tool with multiple cutting edges is moved slowly relative to the material to generate a plane or straight surface. The direction of the feed motion is perpendicular to the tool’s axis of rotation. The speed motion is provided by the rotating milling cutter. The two basic forms of milling are:

- Peripheral milling

- Face milling.

Other conventional machining operations include shaping, planing, broaching and sawing. Also, grinding and similar abrasive operations are often included within the category of machining.

Content from wikipedia.